Discussion

Thiosulfate can

also be standardized against pure copper wire or foil. This procedure is

advantageous when the solution is to be used for the determination of copper because

any systematic error in the method tends to be canceled.

Copper(II) is reduced quantitatively to

copper(I) by iodate ion:

2Cu2+ + 4I-

→ 2CuI(s) + I2

The importance

of CuI formation in the forcing this reaction to completion can be seen from

the following standard electrode potentials:

Cu2+ + e- ↹ Cu+ E0 = 0.15 V

I2

+ 2e- ↹ 2I-

E0 = 0.54 V

Cu2+

+ I- + e- ↹ CuI(s) E0 = 0.86 V

The first two

potentials suggest that iodide should have no tendency to reduce copper(II);

the formation of CuI, however, favors the reduction. The solution must contain

at least 4% excess iodide to force the reaction to completion. Moreover, the pH

must be less than 4 to prevent the formation of basic copper species that react

slowly and incompletely with iodide ion. The acidity of the solution cannot be

greater than about 0.3M, however, because of the tendency of iodide ion to

undergo air oxidation, a process catalyzes by copper salts. Nitrogen oxides

also catalyze the air oxidation of iodide ion. A common source of these oxides

is the nitric acid ordinarily used to dissolve metallic copper and other

copper-containing solids. Urea is used to scavenge nitrogen oxides from

solutions:

(NH2)2CO

+ 2HNO2 → 2N2

(g) + CO2 (g) + 3H2O

The titration of

iodine by thiosulfate tends to yield slightly low results owing to the

adsorption of small but measurable quantities of iodine on solid CuI. The

adsorbed iodine is released only slowly, even when thiosulfate is in excess;

transient and premature end points result. This difficulty is largely overcome

by the addition of thiocyanate ion. The sparingly soluble copper(I) thiocyanate

replaces part of the copper iodide at the surface of the solid:

CuI(s)

+ SCN- → CuSCN(s)

+I-

Accompanying this

reaction is the release of the adsorbed iodine, which thus becomes available

for titrated to prevent interference from a slow reaction between the two

species, possibly

2SCN- +

I2 → (SCN)2

The

standardization procedure is readily adapted to the determination of copper in

the copper alloy that also contains appreciable amounts of tin, lead, and zinc

(and perhaps minor amounts of nickel and iron). The method is relatively simple

and applicable to brasses with less than 2% iron. A weighted sample is treated

with nitric acid, which causes the tin to precipitate as a hydrates oxide of

uncertain composition. Evaporation with sulfuric acid to the appearance of

sulfur trioxide eliminates the excess nitrate, redissolves the tin compound,

and possibly causes the formation of lead sulfate. The pH is adjusted through

the addition of ammonia, followed by acidification with a measure amount of

phosphoric acid. An excess of potassium iodide is added, and the liberated

iodine is titrated with standard thiosulfate.

Procedure

1. Weight

(to the nearest 0.1mg) 0.3g samples into 250 mL conical flasks, and introduce 5

mL of 6 M HNO3 into each; warm (use the hood) until solution is

complete.

Powder of Copper Sample (Pure Copper)

Nitrogen dioxide is evaporating

2. Add

10 mL of concentrated H2SO4, and evaporate (use the hood)

until copious white fumes of SO3 are given off. Allow the mixture to

coll.

3. Cautiously

add 30 mL of distilled water, boil for 1 to 2 min, and again cool.

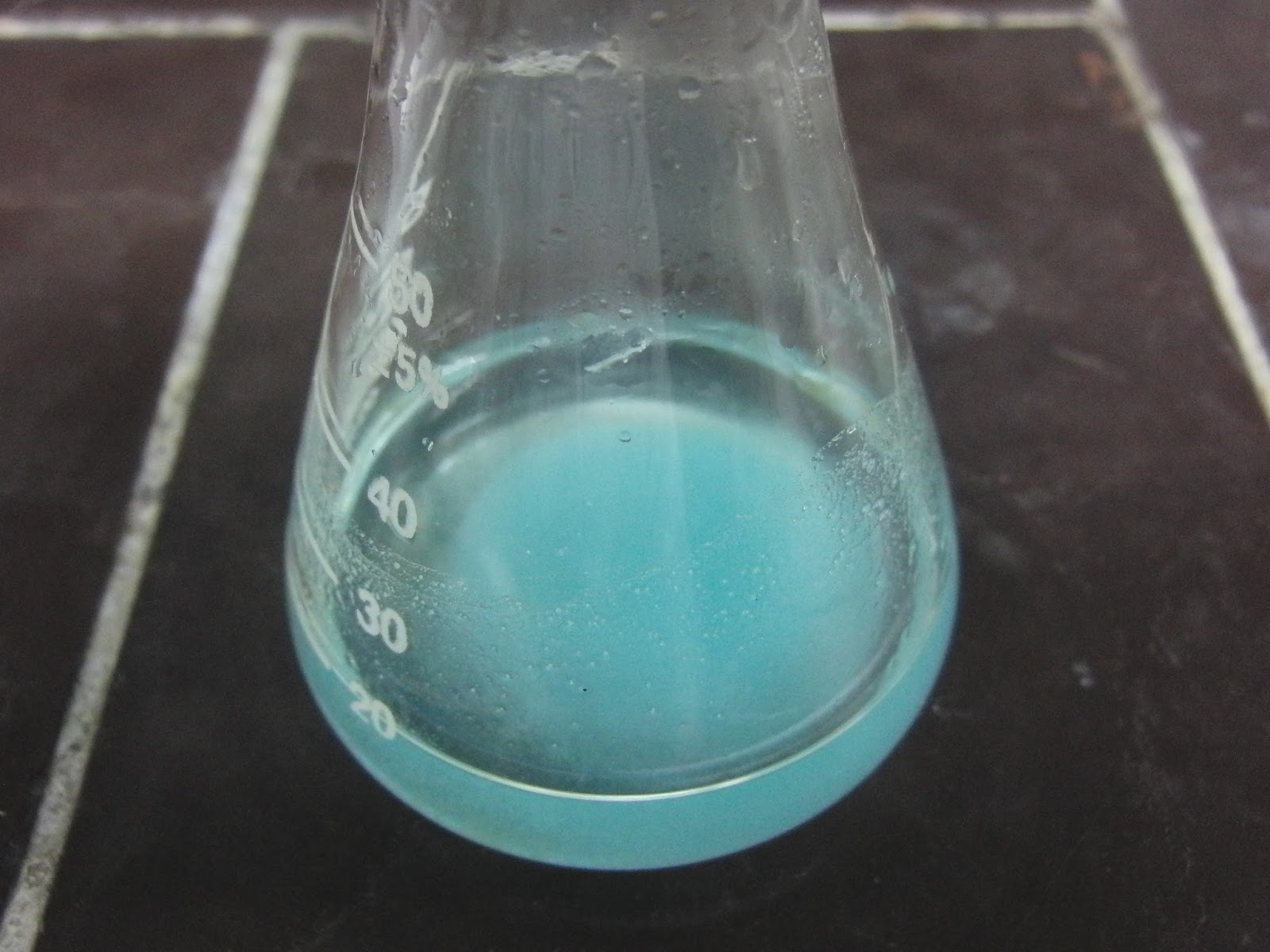

4. Add

concentrated NH3 dropwise and with thorough mixing to produce the

intensely blue Cu(NH3)42+ ; the solution

should smell faintly of ammonia[1].

Some Cu(OH)2 forms at the initial of adding aqueous ammonia

5. Make

dropwise additions of 3 M H2SO4 until the color of the

complex just disappears, and then add 2.0 mL of 85% H3PO4

[2]. Cool to room temperature.

6. Treat

each sample individually from this point on to minimize the air oxidation of

iodine ion. Add 4.0 g of KI to the sample, and titrate immediately with Na2S2O3

until the solution becomes pale yellow.

7. Add 5

mL of starch indicator, and continue the titration until the blue color becomes

fanit.

8. Add 2

g of KSCN; swirl vigorously for 30 s.

9. Complete

the titration, using the disappearance of the blue starch/I2 color

as the end point.

10. Report

the percentage of Cu in the sample.

Notes

[1] Do not sniff

vapors directly from the flask; instead, waft them toward your nose with a

waving motion of your hand.

[2] The H3PO4

can form precipitate with some impurities such as iron and nickel.

Experimental

Record

|

Weight of

Copper Sample

|

0.300 g

|

|

|

= 4.721 mmol

|

|

Molarity of Na2S2O3

|

0.100 M

|

|

Consumption of

Na2S2O3

|

10.80 mL

|

|

|

11.40 mL

|

|

Average

|

11.10

mL

|

|

Weight of

Copper

|

11.10x0.100x(42.5/10.0)

|

|

|

= 4.718 mmol

|

|

Percentage of

Copper in the sample

|

(4.718

/ 4.721) x 100%

|

|

|

= 99.94 %

|

Where you using a specific kind of copper??

ReplyDeletewould the number change significantly if I used A81