Sodium borohydride is an odorless white to

gray-white microcrystalline powder which often forms lumps. It is soluble in

water, without decomposition, however it reacts vigorously with acid solutions.

The salt can be recrystallized by dissolving in warm (50 °C) diglyme followed

by cooling the solution. (Wikipedia)

The reduction of an aldehyde or ketone with

sodium borohydride is straight forward and usually affords a high yield of the

alcohol. The usual procedure (and the one employed in thi sex periment)

involves dissolving the borohydride in 95% ethanol and adding the carbonyl compound

to this solution. To ensure complete reaction, an excess of sodium borohydride

is used.

The reaction between sodium borohydride and

acetophenone is exothermic. Therefore, it is important to add the acetophenone

drop-wise and to control the reaction temperature with an ice bath. After the

reaction has been completed, the excess borohydride and the

ethoxyborohydridesare destroyed with aqueous acid. Because hydrogen gas is

evolved, this treatment with acid must be carried out in a fume hood or a very

well-ventilated room.

Because ethanol, the reaction solvent, is

water-soluble, a clean separation of organic and inorganic products cannot be

achieved by a simple extraction with water and diethyl ether at this point.

(Too much product would be lost in the aqueous ethanol layer.) To circumvent

thisproblem, the first step in the work-up is to boil off much of the ethanol.

In a larger-scale reaction, the ethanol would be distilled and collected. In a

small-scale reaction such as in this experiment, the ethanol can be boiled away

in the fume hood. When most of the ethanol has been removed, the product

1-phenylethanol oils out.

Water and diethyl ether are then added to

the residue for the extraction of the organic compounds from the inorganic

salts. The ether extract is dried with either sodium sulfate or magnesium sulfate.

The crude product is obtained by distilling the ether.

Because of its high boiling point,

1-phenylethanol cannot be distilled at atmospheric pressure. Although it could

be vacuum-distilled, distillation could not separate it from unreacted starting

material (if any) because the two compounds have boiling points only 1E apart.

(An infrared spectrum can be used to determine if any ketone is present in the

product.)

Chemicals

1.

Acetonphenone: 4.000g

2.

Anhydrous sodium sulfate

3.

Diethly ether: ~15mL

4.

95% ethanol: 10mL

5.

3M hydrochloric acid: 3~4mL

6.

Sodium borohydride: 0.500g

Procedure

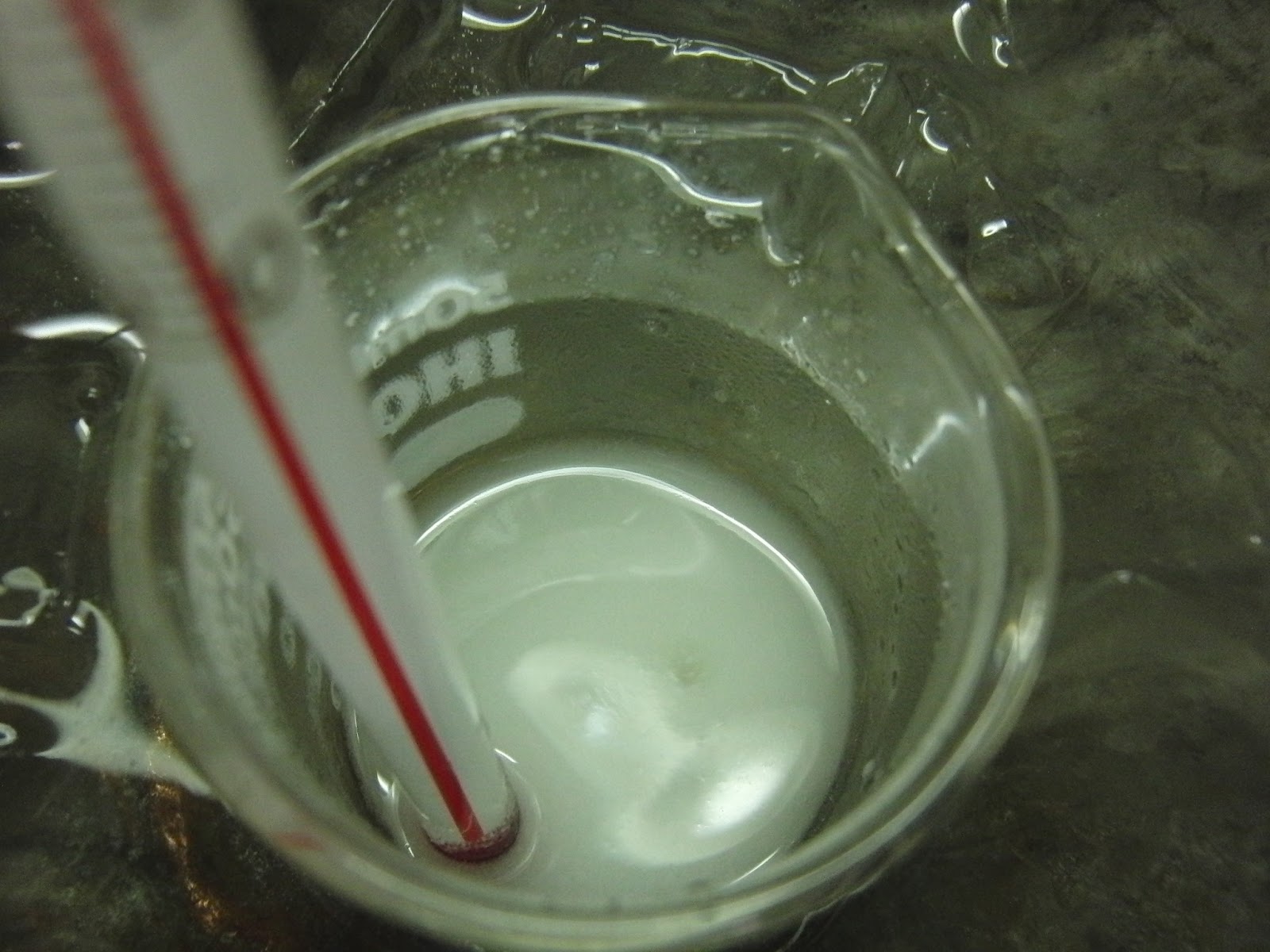

4.

Add the acetophenone dropwise

to the borohydride solution while stirring the mixture continuously. Keep the

temperature of the reaction mixture between 30~50℃ by controlling the rate of addition and

by cooling the beaker in an ice bath.

5.

After the addition is

completed, allow the mixture to stand at room temperature for 15 minutes with

occasional stirring.

8.

Cool the reaction mixture in an

ice bath.

9.

Transfer the mixture in a

separatory funnel and add 7mL diethyl ether and add some water to dissolve the

precipitate.

10. Extract aqueous layer with the diethyl ether and do it again with another

portion of diethyl ether.

11. Combine the ether extracts and wash them with an equal volume of

water.

15. Measure the yield and refractive rate.

Experiment Record

Weight of 1-phenylethanol

|

2.850g

|

Theoretical weight

|

4.066g

|

Yield

|

70.07%

|

Reflective Index in 30.1℃

|

1.5023

|