The aromatic nitration of acetanilide

is an exothermic reaction ; the temperature must be carefully controlled by

chilling, stirring, and the slow addition of reagents. Acetanilide is first dissolved

in the solvent, glacial acetic acid, by warming. Glacial acetic acid is used

because it is a polar solvent capable of dissolving acetanilide and the acetate

ion is a poor nucleophile so no substitution is possible. After the solution is

cooled, sulfuric acid is added; however, even with cooling, the temperature of

the solution rises almost 40E. Both the acetanilide solution and the nitrating

solution (a mixture of HNO3,

and H2SO4) must be chilled to about 10EC before the reaction

is begun.

To prevent dinitration of the

acetanilide, the nitrating mixture is added in small portions to the acetanilide

solution (and not vice versa) so that the concentration of HNO3, is kept at a minimum. After all the

HNO3, H2SO4 solution

has been added, the reaction mixture is allowed to warm slowly to room

temperature. If the reaction mixture has been kept excessively cold during the addition,

there will be a relatively large amount of unreacted HNO3, present, which may cause the

temperature to rise above room temperature. If this should happen, the mixture

must be rechilled.

The work-up procedure consists of

removal of the acids and crystallization of the product. Every trace of acid

must be removed because hydrogen ions catalyze the hydrolysis of the amide to p-nitroaniline

or its protonated cation. Most of the acid is removed by pouring the reaction mixture

onto ice and water, then filtering the flocculent yellow precipitate of

p-nitroacetanilide. The last traces of acetic acid are removed by

neutralization. Because bases also catalyze the hydrolysis of amides, the

neutralizing agent used is disodium hydrogen phosphate (Na2HPO4). This reagent reacts with acids to yield NaH2PO4. The result is a buffered solution with a pH near

neutral.

The crude product is air-dried before

crystallization. If all of the acid was removed, the product will be light

yellow. A deep yellow to yellow-orange product is indicative of the presence of

p-nitroaniline from hydrolysis. Unfortunately, p-nitroaniline is difficult to

remove from p-nitroacetanilide by crystallization.

Mechanism

Preparation of Nitronium Ion:

Nitration

Chemicals

1.

Acetanilide:

1.625g

2.

Disodium

hydrogen phosphate: 3.75g

3.

95%

ethanol: 15mL

4.

Glacial

acetic acid: 2.5mL

5.

15M

nitric acid: 0.875mL

6.

18.4M

sulfuric acid: 3.75mL

Procedure

1. Place 1.625 g of acetanilide in a Erlenmeyer

flask, add 2.5 mL of glacial acetic acid(CAUTION: strong irritant), and warm

the flask on a hot plate in a fume hood until the acetanilide dissolves.

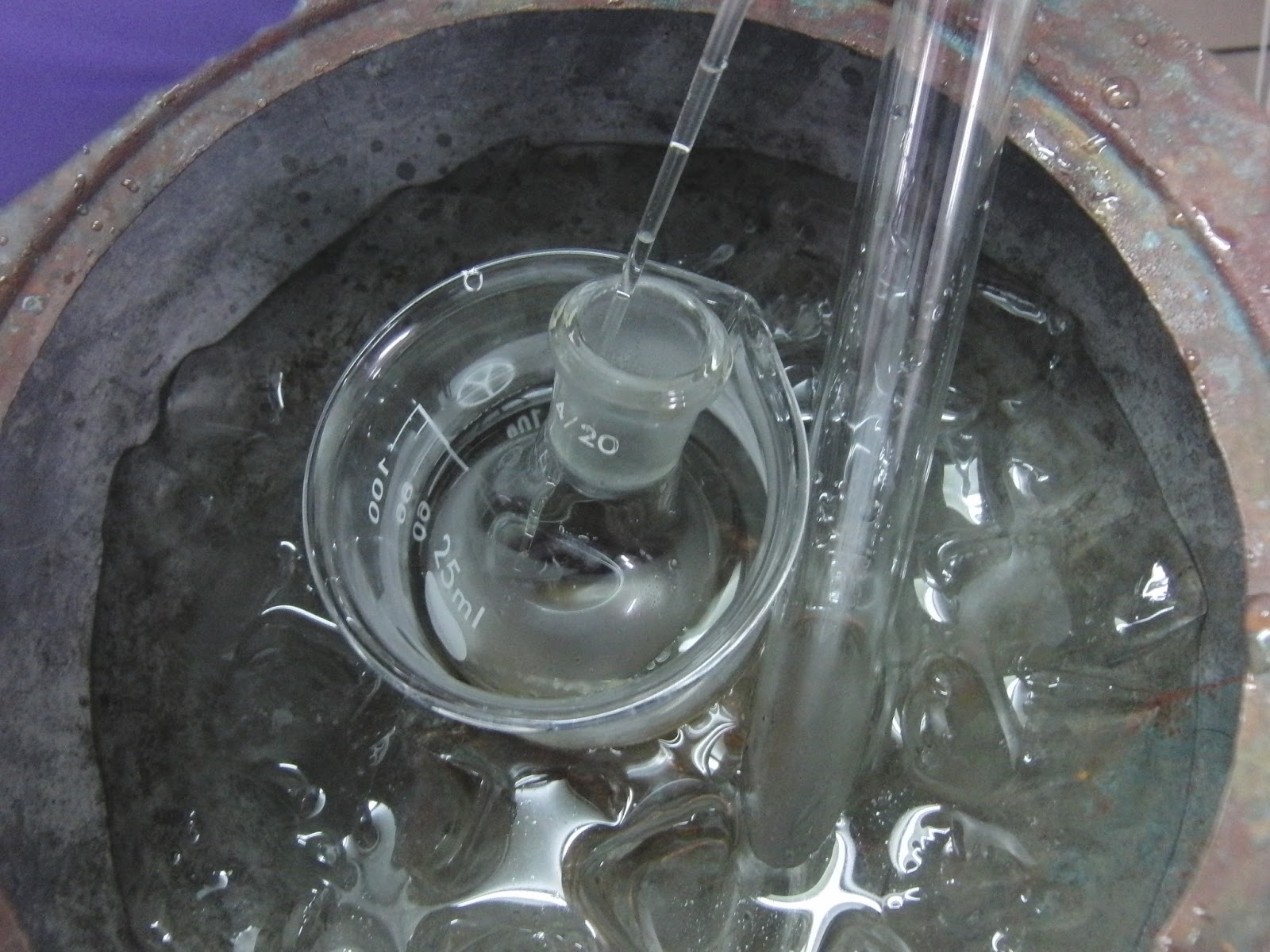

2. Cool the flask in an ice bath to about

20℃

3. Add 2.5 mL of cold, conc. sulfuric

acid. The temperature of the mixture will rise to about 60℃. Chill the solution to about 10℃ in

an ice bath. (The solution will become very viscous.)

4. Mix 0.875 mL of conc. nitric acid and 1.25

mL of conc. sulfuric acid in a test tube, and chill the flask in an ice bath.

5. When both solutions are cold, slowly

add the HNO3, H2SO4 solution, 1 mL at

a time, to the acetanilide solution. Keep the

reaction flask in an ice bath so that the temperature of the reaction mixture

is maintained between 10-20℃. Stir the reaction mixture carefully after each

addition. The entire addition requires about 15 minutes.

6. After the addition is completed, allow

the reaction flask to stand at room temperature for 30 minutes. Monitor the

temperature; if it rises above 25℃, chill the flask in an ice bath. Should the rechilling

be necessary, allow the flask to stand for 30 minutes or more at room

temperature after the rechilling.

7. Pour the reaction mixture into a beaker

containing 25 mL of water and 6.25 g of cracked ice.

8. Using a large Buchner funnel, filter

the heavy lemon-yellow precipitate with vacuum. Press out as much aqueous acid

from the filter cake as possible with a spatula or clean cork while suction is

being applied. The precipitate is voluminous; use care in transferring it to

the Buchner funnel or a substantial amount of product will be lost.

9. Transfer the filter cake to a clean

250-mL beaker, and add 100 mL of 15% aqueous disodium hydrogen phosphate. Stir

the mixture to a paste-like consistency and refilter using vacuum.

10.

Wash

the beaker with two 30-mL portions of cold water. Finally, wash the filter cake

with an additional 50 mL of cold water. Press the filter cake with a spatula or

clean cork to remove as much water as possible, then dry the solid overnight on

a watch glass. Determine the yield and melting point.

Experimental

Record

|

Weight of p-nitroacetanilide(Theory)

|

2.170g

|

|

Weight of p-nitroacetanilide

|

1.650g

|

|

Yield

|

76.0%

|

|

Melting Point of

p-nitroacetanilide (theory)

|

216℃

|

|

Melting Point of

p-nitroacetanilide

|

210~214℃

|

hen hao

ReplyDeletevery precise and correct...

this has really helped me in my practical

Thank you very much!

DeleteThanks a mil!

ReplyDeletewhy the main -major- product is the para isome ????

ReplyDeleteIf I am not mistaken, the acetyl derivative of Aniline is also how manufacturers nitrate aniline,in the protected,or rather deactivated form to control nitration of aniline to successively nitrate to get special explosives? they do this for safety and yield I think. I do know that direct nitration of Aniline by itself can lead to destruction of the aromatic ring, or at least thats what one of my old chemistry books says.

ReplyDeleteY was sulphuic acid added to the solution

ReplyDeleteSulphuric acid acts as dehydrating agent... it absorbs the water which is produced during nitration.... also sulphuric acid is stronger than nitric acid..so it protonates the nitric acid thus generating nitronium ion,which is the electrophile req for nitration.

Deletewhy p-nitroacetanilide is obtained 80% but O-nitroacetanilide is 20%

ReplyDelete